During the cause of test , fluid should be controllably guided into separator and burner after flowing through drilling rod or tubing , the assembly is named as control assembly , which can control the pressure and flow-rate of the pressure and flow-rate of the fluid safely and effectively .

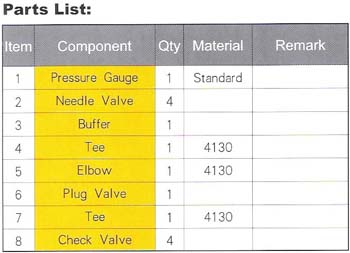

1 .Control head

Jointed with the upper of the test string . Control head is classified into rotary head and un -rotary head of two kinds , and also into three kinds of 35MPa , 70MPa and 105MPa according to the bearing pressure , and it can let the high -pressure fluid flow out of string , but also pump fluid into well .

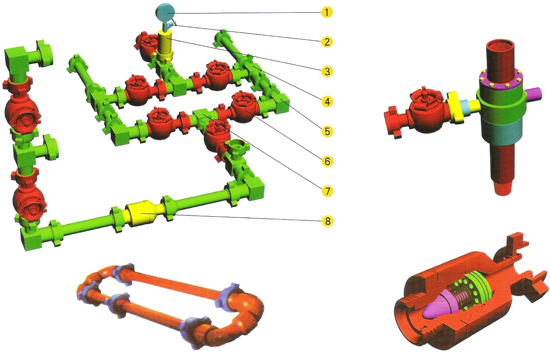

2 .Rigid manifold

Used to control fluid pressure and flow-rate . Rigid manifold is joined with control head upwards and connected with separator and blowout pipeline downwards .

The working pressure includes 35MPa , 70MPa and 105MPa with appropriate test pressure of 70MPa , 105MPa and 140MPa .

3 .Active manifold

Used to joint the control head , manifold and blowout pipeline , the manifold of special EUE seamless steel pipeline union and active elbow .

The working pressure includes 35MPa , 70MPaand 105MPa with appropriate test pressure of 70MPa , 105Ma and 140MPA .

The manifold should be regularly inspected and lubricated . Sealing ring should be replaced and sealing tested to ensure safety in test .

|